Towards Robots That Build

A cohort of new startups are working on automating construction

The world needs more houses.

Housing is one of the biggest drivers of the high cost of living. There just aren’t enough homes, and home construction costs keep going up faster than inflation. And people need more homes than ever, which has resulted in a real housing crunch as high demand meets limited supply. It makes sense, then, that we would look for technological solutions to this problem.

Housing construction is a notoriously demanding industry: it requires lots of physical labor, and is actually quite dangerous — especially jobs like roofing, which will be necessary for construction of most residential homes. Perhaps it should be no surprise that the construction workforce is shrinking, driving yet more demand for automation and further pushing up the cost of construction.

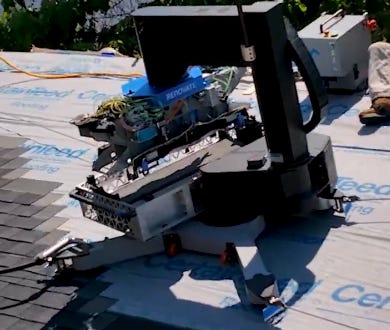

Outside of Amsterdam, a row of eight houses goes up, built by robots. Renovate Robotics is building a robotic roofer. Built Robotics is automating solar pile installation. Gravis robotics is automating excavators. Bedrock Robotics recently emerged from stealth with a spectacular $80 million raise from Eclipse Ventures and 8VC. Robots are moving outside of highly controlled environments and into construction.

Construction Robots in the Real World

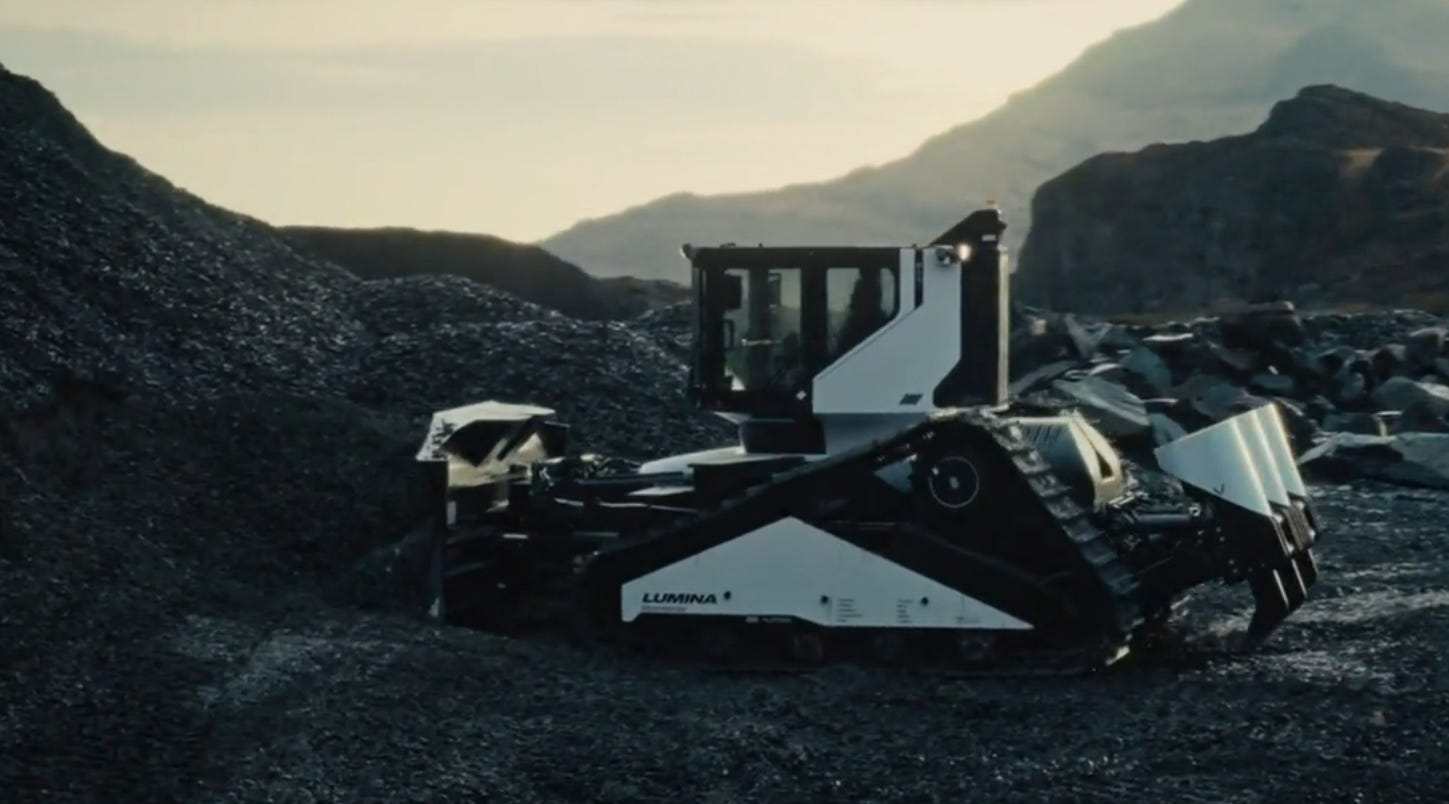

A number of companies — Built, Gravis, and Bedrock, for example — have all looked into automating bulldozers and excavators, retrofitting existing equipment with lidars, cameras, and other sensors.

Take Gravis for an example. From EinPressWire:

At the heart of the system is the Gravis Rack: a rooftop-mounted autonomous control kit that layers real-time 3D surveying, visual situational awareness, geospatial positioning, and performance-focused AI onto the machines you already use. It pairs with the Gravis Slate, a rugged touchscreen interface that makes getting started with autonomy as simple as tapping a finger.

Gravis retrofits existing systems with AI and autonomy to make earthmoving work faster and easier.

Many of these systems seem to take one specific job — filling buckets, driving piles, mounting shingles on a roof — and automate it, in a similar way to traditional robotics and automation. Monumental, for example, is building a fleet of specialized robots that do specific construction jobs, like constructing masonry walls. Others like Teleo Robotics exemplify a shared autonomy approach, making controlling existing hardware much easier.

This makes a lot of sense, for reasons I’ll explain.

Key Challenges Remain

Building fully autonomous construction robots would be very hard. In fact, to me, it seems to check off a full list of problems that make robotic automation difficult to impossible in the short term:

No pre-existing datasets: the large-scale vision language datasets online are all minimally useful for construction tasks

Lots of physical interaction: simulations like NVIDIA Omniverse or MuJoCo will generally not support these tasks well enough to be useful; if it is possible to make these simulations useful, they would need massive amounts of human effort, thus removing some of their advantages.

High precision requirements: buildings are built to specific tolerances, and the robots can’t start making mistakes!

Long horizon tasks: these precision requirements must be maintained over the completion of an entire structure, which is an incredibly long horizon task - one that takes expert humans days to weeks!

All of this means that construction robotics is squarely in its “pre-deep-learning” era. Because traditional, model-based robotics has a fairly predictable formula of human effort → progress, and that it does not take nearly as long or as much data to get something deployed using model-based robotics.

The problem, of course, is that model-based robotics doesn’t scale, usually. It may take a year to automate the first task, but with model-based robotics it’ll take almost as long to automate the second task. That’s why the self driving car companies are moving away from model-based methods:

Self-Driving Taxis Scale Up

Self-driving car company Wayve is doing something big: for the first time they will deploy an autonomous taxi service in London, according to CEO Alex Kendall on X. With this announcement, they join Tesla and Waymo as companies with immanen…

But to get to this point, you need a broad base of data to support the tasks involved, and building that up takes a lot of time. So, for now, it does not seem like we’ll see general purpose construction robots; companies like Built focus on a single vertical, and specialize their systems for performing a single sub-task.

Nothing wrong with this; it’s what traditional automation has looked like for a long time. With modern manufacturing, robotics supply chains, and software tools, it’s possible to take traditional automation out of the factory and move it into the field.

But traditional automation can’t handle real world variability, and so I fully expect that to truly scale, these companies will need to build more and more capable autonomous systems. They’ll need to deploy. to collect data in different circumstances, and improve their robots’ autonomous capabilities.

Growing Momentum

All this being said, construction seems like an area where model-based methods can work very well in the near term. The problems are all very well defined: you really can build a robotic roofer, train exactly the learning-based components you need, and not need it to generalize too much. A human roofer might even still be there, to handle the corner cases your model-based system will fail at. And each robot out there in the world will help lay the groundwork for the next. Shared-autonomy systems, like those produced by Gravis Robotics, will eventually need less and less human intervention, until they’re essentially autonomous - a trajectory also taken by self-driving cars.

There are still relatively few companies operating in this space, but it seems that money, talent, and energy are flowing in. Monumental Robotics raised $25 million back in 2024, for example. And we saw some more news on construction robotics very recently:

July 14, Monumental Labs — working on stone-carving — broke the news that they’d raised an $8 million seed round. Fast Company

July 16, Bedrock Robotics came out of stealth with an $80 million raise

Lumina is rumored to be raising $20-$40 million for electric dozers.

In the near term, we’ll also see lots of companies like Teleo Robotics, which aims to use shared autonomy to make operation of heavy machinery much simpler - instead of automating entire tasks or procedures.

Final Thoughts

The hard work of construction is already changing dramatically, even if we set aside these new robotics startups. Consider this video of Chinese workers teleoperating excavators. Such systems increase workers’ comfort and safety, drive down costs, and generate more of the mountain of data we need to train more powerful and general-purpose robotics models.

There’s a clear route to success here, and when reading about construction robotics startups, I cannot help but think of the self-driving car industry in the early 2010s. There is a well-defined task that needs to be done, and we need to get out there, start building systems, collect the data, and automate it.

As a final note, I started this article with an aside about housing prices. While technology is usually a key driver of social progress, it’s not the only determinant of that progress. In the case of housing, I think the people hoping for a technological solution are doomed to be disappointed: the biggest obstacles to housing — in the western world, at least — are all political, to our great detriment.

But that doesn’t mean technological change like this won’t help. As costs go up, productivity goes down, and demand increases, construction badly needs an injection of real innovation — and I hope this new wave of technology can provide it.

This is a part of a series I am doing on how robotics will change society. The previous post was on robotics in warfare; you can check it out here:

War Always Changes

Important changes have a way of happening slowly, then all at once. Nowhere is this more evident than in warfare.

Didn’t realize construction costs were outstripping inflation.

Traditional housing is certainly hard to automate, though think the 3D-printed housing idea could be more approachable.

Interesting read. As for simulation of construction scenarios, there are physics engines that support this. Checkout AGX Dynamics from Algoryx: http://www.algoryx.com/

There are plenty of papers using AGX for developing solutions for autonomous construction: https://www.algoryx.se/publications/