How Robots Bring You Your Stuff

Robots in shipping and logistics are basically the opposite of the generalizable robotics that we like to talk about and which capture the imagination

The modern port is increasingly an alien place, inhabited by strange creatures that move about, performing their agendas without humans in sight.

Vast container ships arrive at ports like Shanghai, Rotterdam, and Long Beach, where they are greeted by autonomous freight unloading machines, and networks of self-driving ground vehicles that carry containers. Ultimately, the goods end up loaded on trucks and shipped to distribution centers.

And these distribution centers too are highly automated. Amazon has over a million robots now, most of these being shelf-moving robots which help deliver shelves — not packages — to human warehouse workers. Walmart-backed Symbotic, similarly, has something like 20,000 robots deployed in their automated distribution centers, which are huge multi-story structures each one with 40-150 different robots on each floor, totaling hundreds of robots per facility.

We talk a lot about humanoid robots these days, because in many human-facing roles we do need general purpose intelligence and manipulation capabilities. But a warehouse, or a container port, has never been a human environment: it’s an environment designed to fulfill a certain purpose, and that’s basically to redistribute goods so that they make it into the correct human environments in the long run.

So let’s talk about these very inhuman robots.

This post continues an intermittent series on robots in different industries: self driving trucks, construction robots, and military drones.

Port Automation

This post was first touched off by a sequence of posts on social media, in which a video of the Long Beach Container Terminal in California was (wrongly) identified as a Chinese port. There are a growing number of automated ports in the world (here’s video of Rotterdam), and they all follow a similar recipe, made possible by the standardization of the shipping container.

Shipping is one of those things that’s uniquely suited for automation, in part because of the standardized shipping container. Yes, the items in each container might be different; but global standardization — and the employment of the standard “twenty foot-equivalent” container unit, which are all of a common width of 8 feet— has enabled billions of tons of goods to travel the world and has been genuinely revolutionary.

It’s also a boon for robotics because, of course, these containers are standardized, which means that we can build relatively reliable systems using classical (i.e., non-deep-learning) techniques.

Automated ports use a couple different classes of system:

Automated ship-to-shore (STS) cranes: these unload big shipping containers from titanic container ships. Cameras and other sensors keep the cranes stable as they move their heavy cargo.

A terminal operating system (TOS) tracks goods throughout the port.

Automated guided vehicles (AGVs) follow optimal routes to carry containers from ships to the stacking area, or yard.

At the yard, automated stacking cranes (ASCs) pick containers up and put them in storage. They can then be loaded onto trains or trucks for shipping to other distribution centers.

The challenges faced by the TOS are huge; it’s something like a massive game of 3D Tetris, predicting where each container will go so as to minimize unnecessary robot movement while ensuring ships are unloaded and outbound trucks loaded on time.

Robotic Distribution

But that’s only the containers themselves. Containers, as it turns out, are filled with stuff; this stuff needs to get sent to the people who want it for it to have any value.

In robotic distribution centers like those used by Ocado or Symbotic, goods are unloaded from trucks and stored autonomously in a dense, multi-story grid. Autonomous mobile robots (AMRs) move through this grid in response to orders.

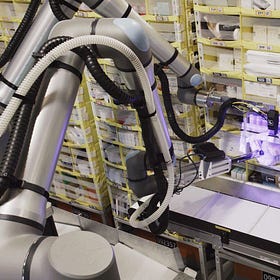

The output of many other distribution centers is the pallet, which will be loaded onto a truck and unpacked, by humans, in a store. One example here is the palletizing solution developed by Symbotic, which you can see here:

A Symbotic facility is ten floors of narrow, low, dark corridors, patrolled by fast-moving robots which place and retrieve the myriad product cases that need to be shipped out to destinations all over the country. As of 2023, Symbotic had 12 fully operational facilities and 35 more in development, and plans to automate all 42 of Walmart’s regional distribution centers.

And of course we have to mention the world’s most prolific robotics company, Amazon. The company has well over a million robots, mostly the shelf-moving robots shown above.

Unlike with Symbotic, which sends pallets loaded with packages to Walmart stores (for example) for unpacking and distribution, Amazon is optimized for sending packages to customer homes. This means that individual boxes need to be prepared with the correct items, not just loaded onto a pallet.

This has created a very different set of incentives: instead of towering facilities filled with fast-moving robots that retrieve boxes for palletization, in Amazon facilities, shelves are brought to human workers to pick and pack the correct boxes to be shipped out on Amazon’s massive fleet of delivery vans.

The Future

There are many parts of this process that still aren’t automated. Amazon is working on robots for picking, including by giving them a “sense of touch”, as we’ve discussed before on this blog:

Giving Robots a Sense of Touch

While we humans are, largely, visual creatures, we can’t solely rely on our eyes to perform tasks. This is a contrast to most modern robotics AI, for which the best practice i…

Boxes from ports need to be loaded into trucks, and shipped from ports to distribution centers, perhaps on a self-driving semi truck like those built by Aurora:

Whatever Happened to the Self Driving Semi?

There are almost three million semi trucks in the United States alone, to the point that trucker is the most common job in 29 states. Most of these are driving 400-600 miles per day along long, straight, predictable highways — a use …

And finally, at some point, the last mile is going to become the obstacle; this is where more interesting and humanlike generalist robots start to become more obviously useful. Work like PhysHSI, as well as the most recent videos from humanoid robotics company Figure, show the future of last-mile delivery.

There are a lot of challenges here, but there’s no reason, then, to believe that in the next decade, something could be brought all the way from a ship to your house with little to no human intervention.

The Politics of Stuff

But, as we’ve seen before, there are non-technical obstacles to this vision of the future.

As I mentioned, this post was inspired in large part by a bunch of posts on social media like this one. A (now deleted) post on X claimed that the video was of a Chinese port, when it’s not. Others quickly followed with, for example, this post about Rotterdam. But it’s illustrative of how political the battle over ports can be.

For instance, the cranes and automated infrastructure here are built by the Shanghai Zhenhua Heavy Industries Company (ZPMC). This has led some to raise security concerns, which so far appear to be baseless. More generally, there’s constantly a battle over port automation; recently the governor of California vetoed a bill that would limit port automation. The result is a push to replace ZPMC machinery with domestic cranes and automation — even if it’s of lower quality.

Perhaps this is natural. Ports, I think, will always be more political — they’re where one country meets the world.

And beside that, all of this touches a lot of jobs. Dockers hate the very idea of port automation, as seen in the discussion about the automation of Rotterdam. Even beyond that, the most common job in the USA is truck driver, carrying goods from one place to another. Millions of people work in the stores and distribution centers. Symbotic’s parent is Walmart, the country’s biggest employer. Most people’s job, one way or another, is in the business of moving things from one place to another.

In a way, logistics and distribution could even be more political than the military robots I’ve written about in the past — we may never see another war between Great Powers, or another war that significantly impacts your day to day life, but you certainly are likely to buy a lot of stuff from Amazon.

Systems like the ones I’ve described, in a very real way, create abundance. They move things from one place to another more easily; they let specialized Chinese factories move goods to people who want them in the West and vice versa. Without trade, we’d all be poorer; and these huge, inhuman robots exist to make it easy for things to move from one place to another.

Small mistake in this line:

“More generally, there’s constantly a battle over port automation more generally;”

Absolutely fascnating deep dive into warehouse and logistics automation. The Symbotic section really highlights how different their approach is from Amazon. Those ten floor facilities with hundreds of fast moving robots in narrow dark corridors sound like something out of science fiction but they're operatng right now. The fact that Symbotic plans to automate all 42 of Walmart's regional distribution centers is enormous, that's basically saying the entire Walmart supply chain will be robotic. What I find intresting about the Symbotic model versus Amazon's shelf moving robots is that it's optimized for pallet level distribution to stores rather than individual package picking for homes. This makes sense for the Walmart use case where stores need pallets of goods for unpacking rather than individual customer orders. The politics section at the end is spot on, these systems create abundance by making distribution more efficient, but the pushback from dockers and truckers is totally understandable when their jobs are at stake. Great post!